Challenging grounds have a means of leaving open every weakness in a job planning. Large clay-baseds growth and shrink with humidity cycles, collapsible sands settle under bunch, and organic packs compress unpredictably. Add limited internet sites, neighboring designs, and also vibration restrictions, as well as also a straightforward commercial create can turn into a geotechnical chess complement. That is actually where resistance stacks as well as their close cousins, helical piles, micropiles, and helical tieback anchors, get their maintain. Utilized appropriately, these deep structure bodies provide reputable capacity, tight quality assurance, as well as predictable efficiency in ground that merely carries out certainly not cooperate.

I have actually dealt with web sites where a nine-story workplace add-on must strand tons via 8 gauges of soft lakebed clays, and also another where a record facility rested over loose filler as well as superficial groundwater. On both, commercial resistance pile installation paired with key use helical piles and micropiles maintained the schedule undamaged as well as the property real. The technique variety is not about trademark name or even buzzwords. It has to do with marrying lots, soil conditions, and also construction restraints along with the right devices and also verification.

What "protection stacks" in fact suggest in the field

Contractors make use of "resistance pile" freely, but in commercial foundation stabilization it usually pertains to hydraulically driven steel stacks that develop ability from end bearing, skin friction, or both. The piles are driven in to the ground using the design's body weight or a gas reaction frame, and also the installment tension is actually used as a proxy for soil resistance. That straight feedback throughout steering is among the technique's best strengths.

Think of it similar to this: you are assessing the ground's reaction along with fully of innovation. If the determines read through reduced, you adjust the length or even the section style before you put pile caps. That sort of real-time management is actually indispensable in changeable soils where typical draft counts or laboratory data may merely go thus far.

Resistance stacks accommodate well together with various other specialty deep foundation repair possibilities:

- Helical heaps use twist to advancement coils to competent strata, offering you setup twist as a capacity red flag in both squeezing and also tension. Micropiles are small-diameter pierced, grouted elements that succeed where overburden is actually unstable but much deeper strata supply rock or even heavy rough soils for bond. Helical tieback anchors as well as other tieback anchors supply lateral restraint and uplift protection for wall surfaces, shoring, and also cranes, as well as likewise maintain buildings versus overturning.

Each device has a sweet spot. On constricted city web sites along with sensitivity to vibrations, commercial helical pile installation as well as micropile installation are typically well. On retrofit work under existing structures, commercial resistance pile installation frequently provides the cleanest access as well as the best practical capacity.

Why difficult grounds ask for resistance piles

Not every ground profile requires deep foundations, but several conditions warrant them swiftly:

- Soft logical layers that extend past traditional spread footing midsts. If your SPT N-values are under 4 for a number of meters, assume long-lasting settlement. A resistance pile moves tons to denser levels below and also sidesteps the creep. Highly variable stuffing. Aged industrial websites can easily conceal particles, ash, and organics. You could over-excavate as well as replace, however digging threat and also dewatering expenses mount quick. Piles punctured the scrap and bear where the ground is actually competent. Expansive clays. When growth pressures intimidate slab heave or even ground uplift, a deep-seated structure decouples the structure from volumetric changes near the surface. High groundwater. Dewatering is actually expensive and can destabilize surrounding buildings. Stacks reduce open excavation opportunity as well as restriction drawdown. Adjacent structures or even utilities that may not allow resonances coming from steered H-piles or compelling compaction. Protection heaps as well as helical piles install with minimal disturbance.

On a health care office project in a tight midtown great deal, we possessed a plain 8 feets of overhanging clearance inside an existing crawlspace as well as a bordering brickwork wall structure that had actually established diagonal fracturing. Steered steel or even wood heaps were out. Helical piles could possibly operate, however up allowance was actually tough for twist heads as well as flighting. The succeeding technique was commercial resistance pile installation with quick segments as well as an unnoticeable hydraulic create. The crew pushed piles coming from within, enjoyed stress readings like war hawks, as well as got to concept capability without a single complaint coming from the neighbor.

Core benefits that turn up in the schedule as well as the budget

Speed on web site frequently steers selection manufacturing, however it is actually not the only lever. The best deep foundation repair answers additionally lessen unpredictability. Resistance pile systems commonly provide on both fronts.

Predictable capacity with direct verification. Installation tension readings correlate along with dirt protection as well as, along with the correct calibration, with permitted ability. You verify the pile during the course of installation, certainly not weeks eventually. For crucial bunches, we still work a couple of compression bunch exams or verification exams, however the bulk of piles depend on installation requirements that helical pile foundations maintain staffs moving.

Minimal spoils. Pressed-in piles create practically no cuttings, a large deal on tainted websites or where fingertip expenses increase. Micropiles and pierced boat docks, through contrast, generate spoils that require handling and also ecological documentation. That performs certainly not create micropiles poor, only that spoils must become part of the calculus.

Compact equipment as well as reduced space ability. Commercial resistance pile installation and also commercial helical pile installation both radiate under low roofings or inside existing buildings. Gas rams and also twist scalps come in sleek styles. I have actually seen prosperous installments under 7 feet of clearance, where the choice would have suggested partial demolition.

Quiet, low-vibration job. Hospitals, labs, and also record facilities may not accept resonance or even noise throughout organization hrs. Pressed stacks and helical anchors are peaceful compared to hammer-driven aspects. That directly equates towards fewer operational interruptions and simpler license commendation in sensitive zones.

Scalability and modular portions. With resistance heaps, steel sections splice swiftly. If you come across a stronger layer quicker, you quit. If you require even more length, always keep pushing sectors. For deep foundation repair under an existing piece, that modularity means small positions, simple mobilization, and exact placement beside pillars or walls.

Matching the pile to the problem

A deep base is not an item; it is a fit-for-purpose component. You decide on based on bunches, soils, gain access to, and tolerance for movement.

Compression lots in smooth clay-baseds and fills up. Protection stacks utilize end bearing at intensity and edge friction along bum rap. In long, smooth clay profile pages, consider stacks along with larger bearing areas or button to helical piles along with various coils to disperse weight. Weight screening will affirm values, yet virtual, style capabilities of twenty to 200 kips every pile are traditional for office projects, along with much higher capabilities achievable in thick layers.

Tension as well as sidewise weights near basement wall surfaces. Helical tieback anchor installation provides you repeatable stress capability considering that installment torque shows bond. Tieback anchors can likewise be grouted supports in denser sands or rock. In bandaged excavations, a blend of helical tiebacks and also soldier pile delaying avoids hefty shoring.

Retrofit below softly filled properties. If the building can easily not supply reaction for pressing, our company bring in a reaction structure. Where soil is too tough for resistance heaps to progress economically, commercial helical pile installation often becomes the preferred road due to the fact that torque scalps carry out the progressing without counting on property weight.

Rock within practical intensity. Micropiles succeed when you can connection into weather-beaten stone or thick rocks. The pierced hole as well as cement develop a high-capacity component in strain as well as compression. Micropiles hold fifty to 300 kips typically, in some cases even more along with longer connects, however they call for careful management of grout and also support and possess spoils and more specialized rigs.

High irregularity throughout the site. Mix as well as match. On one distribution center along with changeable stuffing, our team made use of resistance heaps under indoor cavalcades, helical piles near characteristic collections with resonance limitations, and helical tiebacks for a retaining wall structure that strengthened a ramp. Linking the particulars at the limit beam always kept the building device consistent.

Installation courses that prevent rework

Field efficiency rests on information that rarely suit advertising duplicate. Many patterns have actually saved jobs I have been part of and ought to help any commercial foundation repair effort.

Do certainly not over-rely on one red flag. Installation pressure for protection piles and twist for helical piles are actually great clues, however they are actually not ideal. Clay-based sensitivity, sand quality improvements, as well as tools gradation can easily alter readings. Regularly verify along with at the very least a handful of load examinations or even evidence examinations, and also always keep a calibration contour that matches tension or even twist to confirmed capacity.

Mind oxidation and durability. Steel heaps and also helical turn in assertive soils need preventive measures: increased sacrificial density, hot-dip priming, or even covering. On seaside projects, our company frequently point out 1/8 to 3/16 in propitiatory thickness for a 75 to 100-year life, readjusted through ground resistivity and also chloride content. Micropiles can easily make use of cement cover for oxidation protection, however keep an eye on grout quality as well as cover thickness at transitions.

Control alignment and eccentricity. Heaps perform certainly not such as being actually required around difficulties. Little discrepancies build up. Usage guides at the head, verify plumb with electronic inclinometers where efficient, and steer clear of eccentric braces that develop unexpected instants. When founding along with bracketed resistance heaps, stiff bracket outlining and close fit to the footing are vital to stay away from slippage.

Grout concerns for micropiles and helical tiebacks. Weak cement is actually inaccurate economy. Use an examined mix, management water-cement ratio, as well as file stress. Stress grouting improves connection, but it likewise jeopardizes ground heave if overused. Our company generally develop a ceiling tension and also view adjoining constructs with split assesses for any sort of motion during the course of grouting.

Sequencing may save a framework. Foundation is actually commonly as a lot choreography as design. I prefer alternating heap locations to steer clear of concentrating hoisting powers, after that elevating in stages while keeping track of deflection and also settlement deal aspects. For more mature brickwork, preloading may close groundwork crack repair work by itself, yet do it gradually and document every lift.

Quality management that maintains capability honest

Documentation on commercial resistance pile installation is actually not red tape. It is how you steer clear of pricey callbacks. A well-maintained installment log for each pile that notes sector matter, setup pressure by deepness, rejection problems, and last seating pressure pays dividends. For helical piles as well as helical anchors, the log should grab twist at each helix deepness and also any type of oddities like quick torque drops that might suggest gaps or even retractable soils.

Testing procedures vary through code and also threat profile, but a practical technique blends:

- Pre-production confirmation exams on depictive heaps to validate the layout model. Production verification tests on a portion of piles, usually 2 to 10 per-cent, to capture outliers. Lift and lock-off procedures documented for deriving stacks, along with gauge analyses and resolution readings at benchmark points.

I still observe jobs where an inequality between tools calibration and thought torque element reduces capacity through 20 to 30 percent on paper. A basic cross-check early with a single fixed payload examination rectifies the aspect and prevents dozens of limited piles.

Where protection piles surpass alternatives

No one unit succeeds just about everywhere, but resistance piles hold a couple of trump cards:

Tight access support. When you require to extend a ground or even stabilize a bit of columns in an energetic property, protection stacks squeeze right into rooms where exercise rigs may unsuitable. A two-person crew, a little gas set, and also a stack of steel sectors can easily derive a bay in a day.

Immediate bunch move. Since resistance stacks are pressed versus the structure and settled to tension, you may elevate or even support immediately. Grouted bodies, including micropiles as well as grouted anchors, usually need to have a wait for durability increase, frequently 24 to 72 hrs depending on mix and also temperature.

Little to no vibration. Historical brickwork, labs, and also facilities along with delicate devices gain from the silent procedure. I have viewed accelerometers barely shift during pressing, while a block away, conventional driving would have induced formal complaints.

Adaptability to unknown intensity. The modular attributes of resistance piles indicates you carry out certainly not require ideal geotechnical data to organize section durations. Bring additional portions on the truck, and also the staff can respond to actual disorders. That adaptability keeps change orders sensible also when borings are sparse.

How the pieces converged on business projects

Let us walk through a common series for a deep foundation repair where resistance piles share show business along with helical piles as well as tieback anchors.

Site examination sets the tone. Two or 3 borings on a tiny footprint is actually hardly enough when the soils are actually recognized to differ. If finances are actually limited, at least plan for even more exploratory probing during the course of the very first time of installation. In one warehouse retrofit, probing located a hidden concrete slab below filler in the northeast corner. Our team switched those places to helical piles to stay clear of blockage problems while maintaining resistance stacks elsewhere.

Design blends systems. Cavalcade collections along with greater tons obtain arranged along with heaps that achieve much deeper bearing levels. Border wall surfaces near residential property series, where lateral stress and also construction fence limit devices, receive helical tieback anchors to stand up to sidewise planet stress. The tiebacks likewise protect against wall structure action during digging for brand new utilities.

Permitting favors low-impact job. Domestic evaluators frequently like commercial helical pile installation and also commercial resistance pile installation over driven alternatives due to minimized sound. When a task staff can reveal a plan along with minimal spoils as well as no resonance cases, commendations relocate quicker.

Fieldwork carries out with tiny crews. Resistance piles mount under footings through little pits or even center openings. Where displacement develops, ports lift incrementally, and also braces lock off loads. Helical piles breakthrough with a portable twist scalp, usually on a skid guide or even mini-excavator. Tieback anchors punch or even torque into the kept ground, with proof screening on a subset. Micropiles, if used, comply with an even more intentional rhythm: practice, place bar or even casing, grout, test.

Structural closure and also monitoring finish the work. Pile caps and grade beams tie elements with each other. The team puts up negotiation point in times on the structure to validate that actions remain within restrictions over the very first couple of months. If foundation crack repair belonged to the extent, check those fractures along with telltales to validate that width stabilizes after payload transfer.

Addressing typical worries coming from owners and also facility managers

Owners ask the same questions around markets, as well as they ought to have trustworthy answers.

Will functions be interfered with? Resistance pile as well as helical pile work is actually relatively quiet. In numerous office as well as medical care setups, we schedule louder portions at the edges of the workday and maintain daytime tasks effectively within background noise. Vibration amounts are actually commonly purchases of immensity less than steered piles or heavy demolition.

How expected is the ultimate expense? Better than most deep base alternatives, offered the contractor is actually experienced. Considering that manufacturing rates are higher and also tools is easy, effort is actually controlled. The primary variables are heap size and also the occasional obstacle. A contract structured with unit prices for extra sectors specifies requirements and also stays clear of surprises.

What regarding long-lasting functionality? Durability is actually a feature of three points: deterioration protection necessary to the site, right bunch transmission into the establishment, as well as affordable company lots for the pile kind. When those are lined up, protection heaps, helical piles, as well as micropiles all provide multi-decade life span. For critical resources, our experts pair stacks along with keeping track of thus trends are actually captured just before they become issues.

Can these techniques be actually utilized for brand new construction or even merely fixings? Both. While several consider these as structural foundation repair resources, commercial helical pile installation and resistance stacks find extensive usage in brand new development, specifically on unsatisfactory grounds. They reduce excavation, restriction dewatering, as well as minimize schedules. Tieback anchors are typical meals for permanent maintaining walls, basements, as well as short-term shoring.

Where protection heaps struggle, as well as what to carry out about it

No strategy is flawless. Protection stacks have limitations, and recognizing them very early makes tasks smoother.

Insufficient response. Mashing piles needs reaction against the structure or even a frame. Lightweight designs may certainly not supply enough reaction to obtain intended pressures. Solutions feature response frameworks, preloading, or even switching to helical piles that perform not rely on response in the exact same way.

Shallow experienced levels along with obstructions. If you rapidly comply with thick gravel along with cobbles or even rubble, the pressed heap may reject prematurely without obtaining aim at capacity. Switching to helical piles along with proper helix sizes or utilizing a pilot bore can navigate by means of. Conversely, a small-diameter predrill can easily appear the impediment to permit continuous pressing.

Highly collapsible or even invalidated dirts. Sinkhole-prone karst or mine gaps complicate any type of deep-seated groundwork. Micropiles with pressure-grouted connects and post-grouting might be safer listed below, as they may link little voids as well as generate a trustworthy connection in stone or even dense strata.

Extreme side requirements. Resistance heaps lug lateral bunches poorly unless organized as well as tied with grade beams, as well as also then, their side tightness could be confined. For keeping wall structures or even basement pieces along with higher side forces, helical tieback anchors or even grouted tiebacks belong in the design.

Practical support for defining and also executing

Specifications frequently direct project results much more than any industry heroics. A handful of practices regularly improve results:

- Define recognition requirements plainly. For resistance piles, point out target installation stress, conduct opportunities, and minimum embedment. For helical piles, determine the torque connection element as well as minimum required depth for coils. For micropiles, particular grout strength, connect size, and also bar size. Require a preproduction examination plan. A few examinations up front avoid production improvements midstream. For normal office projects, 2 squeezing tests and one stress test may tune the requirements. For tieback anchors, proof exam each support as well as achievement exam a portion based upon risk. Keep delegations sensible. Request tools capacities, calibration reports, and also setup programs that match the site constraints. Limitation burdensome paperwork that performs certainly not influence quality. Coordinate along with the structural developer on brackets and also limits. Underpinning braces must fit true footings, not idealized ones. Documentation bolstering steel disputes and also embedment. Easy rebar modifications in the course of preconstruction conferences spare days later. Plan tracking. Settlement aspects, split determines, and also, where needed to have, resonance as well as sound displays are actually low-cost insurance coverage. Information relaxes concerned stakeholders and also confirms that the job achieved the planned stability.

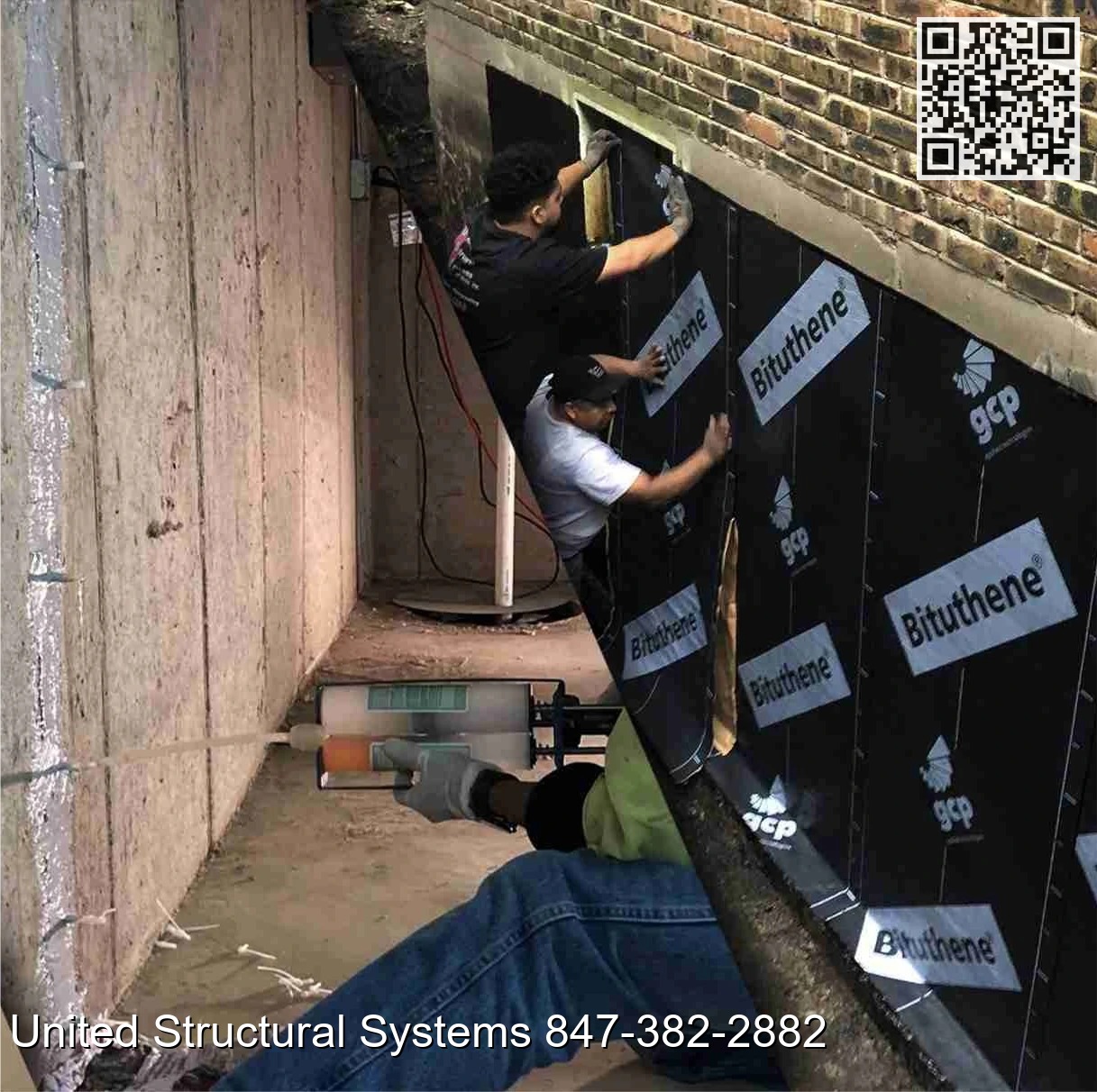

A brief keep in mind on foundation crack repair in the mix

Cracks in wall surfaces or even slabs commonly activate decision for assistance, however crack injection alone seldom deals with the underlying source. Epoxy or polyurethane may close as well as also rejuvenate some tensile continuity across a crack, however if the dirt remains to relocate, the split will definitely reopen or migrate. In practice, our company stabilize the base to begin with making use of resistance heaps, helical piles, or micropiles, then deal with splits. On a block exterior along with stepped cracking from differential negotiation, our experts underpinned along with resistance stacks to halt motion, raised a fraction of an in to recover positioning, after that stitched as well as repointed the stonework. The pattern matters much more than the brand of treatment resin.

Cost, timetable, and also value the owner can easily bank on

On a straight foot base, centered base systems can appear pricey reviewed to spread out footings. That comparison is actually misleading. In bad soils, the real alternatives are certainly not superficial grounds however deeper excavation with haul-off, dewatering, and also substitute, or a ground enhancement course along with its own equipment and also routine. Stacks consolidate the job: low excavation, prompt setup, and verified capability. On a 60,000-square-foot renovation where we maintained 78 columns, the resistance pile service trimmed down four weeks off the routine and decreased dewatering threat to near absolutely no. The manager cared much less regarding the per-pile cost as well as more about opening on time.

The profits for daunting soils

Commercial resistance pile installment is actually certainly not a silver bullet, but it is one of the best trustworthy devices for maintaining and also holding structures in stubborn ground. Matched carefully with commercial helical pile installation, micropiles, and helical tieback anchor installation, it supplies a versatile toolkit for deep foundation repair and brand new builds equally. The advantages are actually substantial: real-time proof of ability, silent and small operations, low spoils, as well as adaptability Hop over to this website when the dirt profile improvements coming from one corner of the website to the next.

If you are actually weighing alternatives for commercial foundation repair or structural foundation repair on a challenging internet site, start with an honest consider the soil records and also the restraints of the structure. After that pick the heap kind that ideal matches the lots and also strategies. Oftentimes, a mixed service provides the best worth. The secrets are disciplined screening, clear approval requirements, and area teams who recognize just how to pay attention to the ground with every push, turn, and lift. When those factors straighten, also the most challenging soils become workable, and also commercial foundation stabilization stops being actually a wager and comes to be a measured procedure along with outcomes you can trust.